NORMA GBS Heavy Duty T Bolt Hose Clamp – W4 Full Stainless

The NORMA GBS W4 Stainless Steel T Bolt Hose Clamp offers unmatched durability and corrosion resistance, ideal for securing hoses in heavy-duty applications. Its robust design ensures a secure, leak-proof connection, making it essential for industrial use.

$6.51 – $3,322.00 Inc. GST

NORMA GBS Heavy Duty T Bolt Hose Clamp – W4 Full Stainless

Introducing the NORMA GBS Heavy Duty T Bolt Hose Clamp – W4 Full Stainless, a pinnacle of engineering designed to meet the most rigorous demands in securing hoses. Crafted entirely from Stainless Steel AISI 304, this clamp is the solution for applications demanding high durability and corrosion resistance.

Whether it’s for suction and pressure hoses with plastic or steel inserts or for high shore hardness values, this clamp ensures a robust, leak-proof connection. Its exceptional band tensile force capacity stands out, making it perfect for commercial vehicles, industrial machinery, and special applications.

This exceptional clamp is not only about strength; its ease of installation is unmatched. Whether you’re using manual, pneumatic, or electrical tools, its user-friendly design guarantees a hassle-free application. The specially designed bolt with an integrated spacer enhances performance, while the mechanically locked closure avoids welding spots, eliminating contact corrosion.

The band’s robust design with rounded edges is engineered to prevent injuries and damage to hoses, coupled with hollow trunnions to minimize tensile forces. This design ethos extends the life of the clamp and the hoses it secures.

Key Advantages:

- Doubling of failure torques for unmatched security.

- Tripling of band tensile force levels for superior hold.

- Full stainless steel construction for maximum durability and corrosion resistance.

Applications: Its versatility makes it suitable for machine building, the chemical industry, irrigation systems, ship manufacturing, the railway industry, agricultural and building machines, engine manufacturing, pump and filter systems, and the mining industry.

The NORMA GBS Heavy Duty T Bolt Hose Clamp – W4 Full Stainless is more than just a clamp; it’s a commitment to quality, durability, and reliability. Whether securing hoses in harsh outdoor environments or ensuring the safety and efficiency of machinery, this clamp is the professional’s choice for a reason.

| Band Width | Part Number | Clamping Range (mm) | W1 | W2 | W4 |

|---|---|---|---|---|---|

| 18 | GBS18/18 | 17-19 | ✓ | ✓ | ✓ |

| 18 | GBS20/18 | 19-21 | ✓ | ✓ | ✓ |

| 18 | GBS22/18 | 21-23 | ✓ | ✓ | ✓ |

| 18 | GBS24/18 | 23-25 | ✓ | ✓ | ✓ |

| 18 | GBS26/18 | 25-27 | ✓ | ✓ | ✓ |

| 18 | GBS28/18 | 27-29 | ✓ | ✓ | ✓ |

| 18 | GBS30/18 | 29-31 | ✓ | ✓ | ✓ |

| 18 | GBS33/18 | 31-34 | ✓ | ✓ | ✓ |

| 18 | GBS36/18 | 34-37 | ✓ | ✓ | ✓ |

| 18 | GBS39/18 | 37-40 | ✓ | ✓ | ✓ |

| 18 | GBS42/18 | 40-43 | ✓ | ✓ | ✓ |

| 20 | GBS45/20 | 43-47 | ✓ | ✓ | ✓ |

| 20 | GBS49/20 | 47-51 | ✓ | ✓ | ✓ |

| 20 | GBS53/20 | 51-55 | ✓ | ✓ | ✓ |

| 20 | GBS57/20 | 55-59 | ✓ | ✓ | ✓ |

| 20 | GBS61/20 | 59-63 | ✓ | ✓ | ✓ |

| 20 | GBS66/20 | 63-68 | ✓ | ✓ | ✓ |

| 25 | GBS71/25 | 68-73 | ✓ | ✓ | ✓ |

| 25 | GBS76/25 | 73-79 | ✓ | ✓ | ✓ |

| 25 | GBS82/25 | 79-85 | ✓ | ✓ | ✓ |

| 25 | GBS88/25 | 85-91 | ✓ | ✓ | ✓ |

| 25 | GBS94/25 | 91-97 | ✓ | ✓ | ✓ |

| 25 | GBS101/25 | 97-104 | ✓ | ✓ | ✓ |

| 25 | GBS108/25 | 104-112 | ✓ | ✓ | ✓ |

| 25 | GBS117/25 | 112-121 | ✓ | ✓ | ✓ |

| 25 | GBS126/25 | 121-130 | ✓ | ✓ | ✓ |

| 30 | GBS135/30 | 130-140 | ✓ | ✓ | ✓ |

| 30 | GBS145/30 | 140-150 | ✓ | ✓ | ✓ |

| 30 | GBS156/30 | 150-162 | ✓ | ✓ | ✓ |

| 30 | GBS168/30 | 162-174 | ✓ | ✓ | ✓ |

| 30 | GBS181/30 | 174-187 | ✓ | ✓ | ✓ |

| 30 | GBS195/30 | 187-200 | ✓ | ✓ | ✓ |

| 30 | GBS207/30 | 200-213 | ✓ | ✓ | ✓ |

| 30 | GBS220/30 | 213-226 | ✓ | ✓ | ✓ |

| 30 | GBS233/30 | 226-239 | ✓ | ✓ | ✓ |

| 30 | GBS246/30 | 239-252 | ✓ | ✓ | ✓ |

| 30 | GBS259/30 | 250-265 | ✓ | ||

| 30 | GBS272/30 | 265-278 | ✓ | ||

| 30 | GBS311/30 | 304-317 | ✓ | ||

| 30 | GBS324/30 | 317-338 | ✓ |

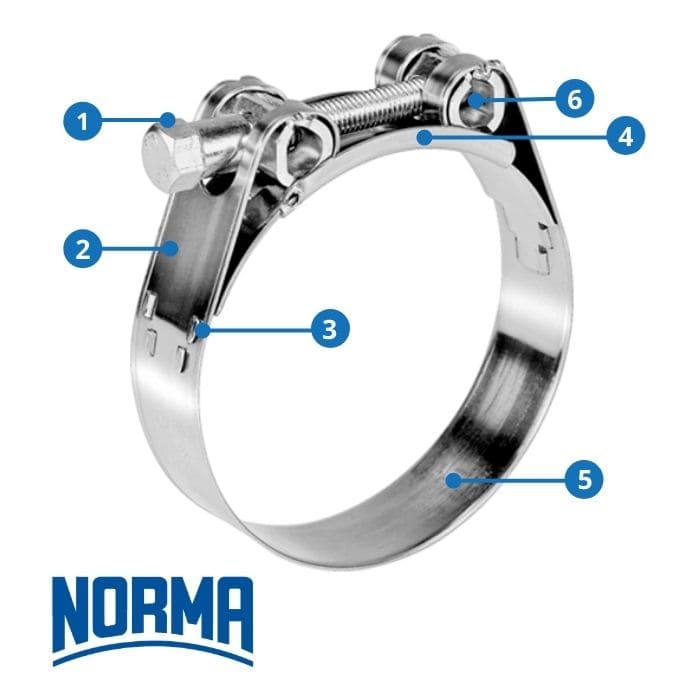

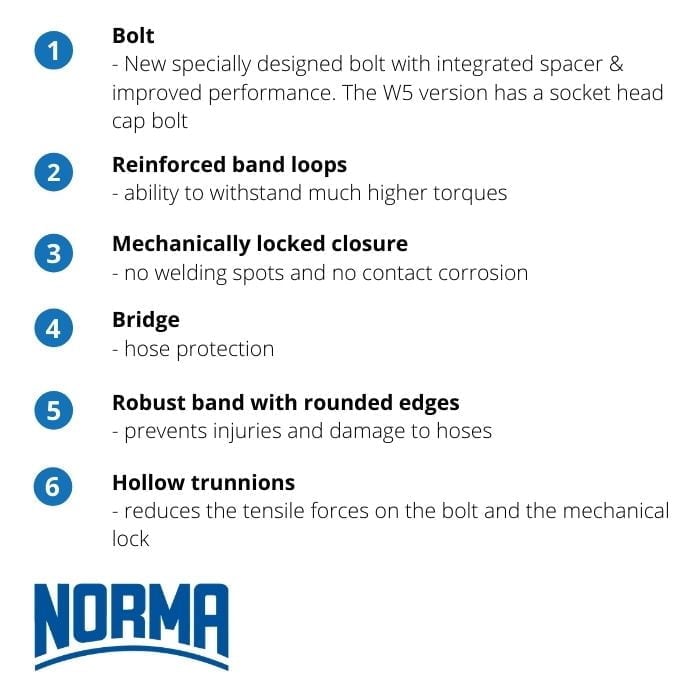

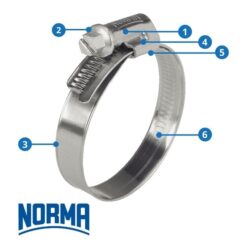

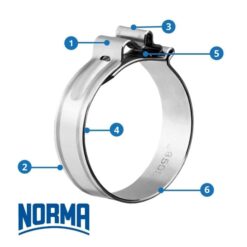

1. Bolt

– New specially designed bolt with integrated spacer and improved performance. The W5 version has a socket head cap bolt

2. Reinforced band loops

– Ability to withstand much higher torques

3. Mechanically locked closure

– No welding spots and no contact corrosion

4. Bridge

– Hose protection

5. Robust band with rounded edges

– Prevents injuries and damage to hoses

6. Hollow trunnions

– Reduces the tensile forces on the bolt and the mechanical lock

| Material | Stainless Steel |

|---|---|

| Fitting Type | Clamps |