NORMA TORRO® Worm Drive Hose Clamp – W1 Full Galvanised

The NORMA TORRO® Worm Drive Hose Clamp – W1, entirely galvanized steel, offers unmatched durability and clamping force. Ideal for demanding applications, it ensures optimal sealing and hose protection across automotive, marine, and industrial sectors with its asymmetrical construction and wide range compatibility.

$7.37 – $807.40 Inc. GST

NORMA TORRO® Worm Drive Hose Clamp – W1 Full Galvanised

The NORMA TORRO® Worm Drive Hose Clamp, crafted entirely from galvanised steel (W1), stands as a pinnacle of hose clamp engineering. This clamp is specifically designed to meet the high mechanical demands of various applications, making it an indispensable tool across a broad spectrum of industries. Its unique asymmetrical construction, a hallmark of the NORMACLAMP® TORRO® range, ensures high force, superior torque, and an even distribution of clamping pressure, aligning perfectly on the hose for optimal sealing.

Advantages:

- Multi-range hose clamp designed for high mechanical loads.

- Entirely made from galvanised steel for durability and corrosion resistance.

- Patented one-piece offset housing ensures optimum sealing performance.

- Smooth solid band with rolled edges protects hoses from damage.

- Wide clamping ranges, accommodating diameters from 8-12 mm to 180-200 mm according to DIN 3017, making it versatile for various applications.

Applications:

- Ideal for securing cooling water lines, fuel lines (both depressurised and pressurised), and ventilation systems.

- Essential for connections in sanitary applications, machine building, the household appliance industry, and hose lines in commercial vehicle industries.

- Used in automotive and marine industries for vacuum and pressure fuel and vent lines.

- Plays a crucial role in the white goods and commercial and industrial sectors.

The NORMA TORRO® Worm Drive Hose Clamp – W1 Full Galvanised is celebrated for its robust construction, ease of installation, and exceptional sealing capabilities. It’s the go-to choice for professionals seeking reliable, durable, and efficient hose clamping solutions. Whether it’s for automotive, marine, industrial machinery, or commercial applications, this clamp provides a secure, tight fit that withstands the rigors of high mechanical loads, ensuring the integrity and safety of hose connections.

| Band Width | Part Number | Clamping Range (mm) | W1 Alu-zinc band M/Steel Housing & Hex Screw | W2 Stainless Steel Band 1.4016 M/Steel Housing & Screw | W3 All Stainless Steel 1.4016 (430) | W4 All Stainless Steel 1.4301 (304) | W5 All Stainless Steel 1.4401 (316) |

|---|---|---|---|---|---|---|---|

| 7.5 | 8-12/7.5P | 8-12mm | ✓ | ✓ | |||

| 7.5 | 10-16/7.5P | 10-16mm | ✓ | ✓ | |||

| 9 | 8-12/9P | 8-12mm | ✓ | ||||

| 9 | 8-16/9P | 8-16mm | ✓ | ✓ | ✓ | ||

| 9 | 10-16/9P | 10-16mm | ✓ | ||||

| 9 | 12-20/9P | 12-20mm | ✓ | ✓ | ✓ | ✓ | |

| 9 | 12-22/9P | 12-22mm | ✓ | ✓ | |||

| 9 | 16-25/9P | 16-27mm | ✓ | ✓ | ✓ | ||

| 9 | 20-32/9P | 20-32mm | ✓ | ✓ | ✓ | ||

| 9 | 25-40/9P | 25-40mm | ✓ | ✓ | ✓ | ||

| 9 | 30-45/9P | 30-45mm | ✓ | ✓ | ✓ | ||

| 9 | 32-50/9P | 35-50mm | ✓ | ✓ | ✓ | ||

| 9 | 40-60/9P | 40-60mm | ✓ | ✓ | ✓ | ||

| 9 | 50-70/9P | 50-70mm | ✓ | ✓ | ✓ | ||

| 9 | 60-80/9P | 60-80mm | ✓ | ✓ | ✓ | ||

| 9 | 70-90/9P | 70-90mm | ✓ | ✓ | ✓ | ||

| 9 | 80-100/9P | 80-100mm | ✓ | ✓ | ✓ | ||

| 9 | 90-110/9P | 90-110mm | ✓ | ✓ | ✓ | ||

| 12 | 16-27/12P | 100-120mm | ✓ | ✓ | ✓ | ||

| 12 | 20-32/12P | 110-130mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 25-40/12P | 120-140mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 30-45/12P | 130-150mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 35-50/12P | 140-160mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 40-60/12P | 150-170mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 50-70/12P | 160-180mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 60-80/12P | 170-190mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 70-90/12P | 180-200mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 80-100/12P | 190-210mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 90-110/12P | 200-220mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 100-120/12P | 210-230mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 110-130/12P | 230-250mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 120-140/12P | 260-280mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 130-150/12P | 280-300mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 140-160/12P | 140-160mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 150-170/12P | 150-170mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 160-180/12P | 160-180mm | ✓ | ✓ | ✓ | ✓ | |

| 12 | 170-190/12P | 170-190mm | ✓ | ||||

| 12 | 180-200/12P | 180-200mm | ✓ | ✓ | |||

| 12 | 190-210/12P | 190-210mm | ✓ | ||||

| 12 | 200-220/12P | 200-220mm | ✓ | ||||

| 12 | 210-230/12P | 210-230mm | ✓ | ✓ | |||

| 12 | 230-250/12P | 230-250mm | ✓ | ✓ | |||

| 12 | 260-280/12P | 260-280mm | ✓ | ✓ | |||

| 12 | 280-300/12P | 280-300mm | ✓ | ✓ |

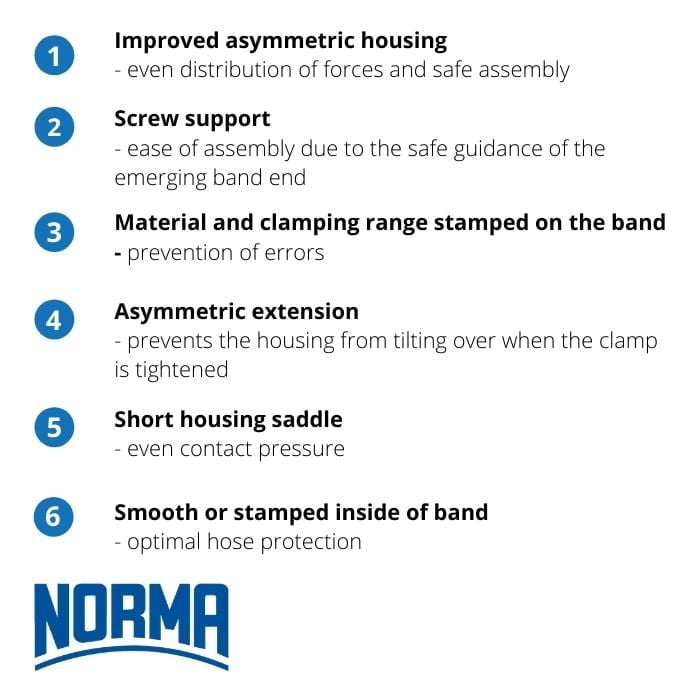

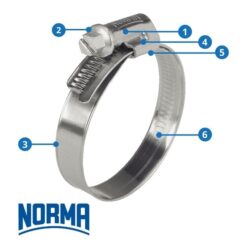

1. Improved asymmetric housing

– even distribution of forces and safe assembly

2. Screw support

– ease of assembly due to the safe guidance of the emerging band end

3. Material and clamping range stamped on the band

– prevention of errors

4. Asymmetric extension

– prevents the housing from tilting over when the clamp is tightened

5. Short housing saddle

– even contact pressure

6. Smooth or stamped inside of band

– optimal hose protection

| Material | Galvanised |

|---|---|

| Fitting Type | Clamps |