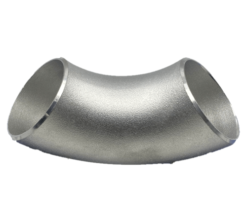

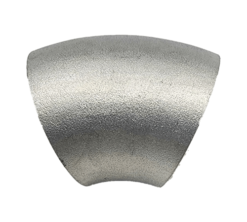

Buttweld Fittings

Valve Warehouse Australia presents an extensive collection of Buttweld Fittings, renowned for their exceptional strength, adaptability, and ease of welding. These buttweld fittings are indispensable in a multitude of Australian industries, including construction, oil and gas, shipping and water management.

Our selection of Carbon Steel Buttweld Fittings is designed to withstand high-pressure environments, with a continuous working temperature rating of up to 450°C and with maximum pressure ratings of up to 5000 PSI. Our inventory includes but is not limited to elbows, tees, concentric and eccentric reducers, caps, long and short radius bends, available in sizes ranging from 15mm (1/2″) to 700mm (28″). We ensure the durability and reliability of our products by offering a 2-year warranty on all our Buttweld Pipe Fittings.

Our Online Valve & Fitting Superstore boasts a vast range of competitively priced Buttweld Fittings in Australia. With an extensive array of sizes and types, our stock is guaranteed to meet your project’s specifications at unbeatable prices. Enjoy the perks of Flat Rate Shipping Australia-Wide or Free Shipping on orders over $100, along with Volume Discounts of up to 20% OFF. Plus, we offer a Price Beat Guarantee to ensure you get the best deal.

Standards that go beyond expectations

Our Buttweld Fittings not only meet but exceed industry standards such as AS/NZS 4035, ASME B16.9, and ASTM A234. Manufactured to the exacting requirements of AS/NZS 4087:2011, these fittings ensure durability even under the most extreme conditions. Precision-engineered in renowned facilities, our Buttweld Fittings are designed to perform under high pressure and are tested for quality assurance, ensuring lasting performance in diverse industrial applications.

Secure your welds with Carbon Steel

Carbon Steel Buttweld Fittings are engineered for unmatched strength, offering exceptional resistance to high temperatures and pressures, which safeguards them from wear and corrosion. However, it's crucial to understand that not all Carbon Steel Buttweld Fittings are manufactured to the same caliber of excellence. Some alternatives might compromise on quality for cost, failing to meet the rigorous standards that our products adhere to. Opting for Valve Warehouse Australia as your supplier means choosing reliability and superior performance. Our Carbon Steel Buttweld Fittings stand out for their durability and resilience, ensuring a dependable and long-lasting solution for any application.

Pair your Buttweld Fitting with our range of Flanges

Efficient water flow is key in any setup. To help you achieve this, we offer a wide range of high-quality Flanges to pair with your Buttweld Fittings. Our flanges are designed to fit perfectly and work smoothly whether you want to connect pipes, valves, pumps and other equipment and whether you're building something new or improving what you have. They're made to be strong and reliable, helping to keep water moving as it should.

Our Team is Ready to Assist!

Our dedicated team, boasting a collective experience of over 100 years in plumbing and fittings, is prepared to assist you. Get expert guidance from us to make informed choices for your next project. Reach out to us today info@valvewarehouseaustralia.com.au or call (03) 9421 0042.

Frequently Asked Questions

Although not an Australian standard, it's widely accepted in Australian engineering practices for the dimensions, tolerances, and design of carbon steel buttweld fittings.

ASME B16.25 Buttwelding EndsSpecifies the preparation of buttwelding ends of piping components to be joined into a piping system by welding. It's commonly used in conjunction with ASME B16.9 for carbon steel fittings.

ASTM A234 / A234M Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature ServiceSpecifies requirements for wrought carbon steel and alloy steel fittings of seamless and welded construction. While an ASTM (American Society for Testing and Materials) standard, it's frequently referenced in Australian projects for material specifications of buttweld fittings.

AS/NZS 4793:2009 Mechanical joining of polyethylene and polypropylene pipes and fittings for pressure applicationsThis standard is more specific to polyethylene and polypropylene, but it's relevant in the context of how non-metal fittings might integrate with metal systems, including carbon steel buttweld fittings in composite systems.

AS 2129 Flanges for Pipes, Valves and FittingsThough primarily focused on flanges, this standard is relevant for integrated piping systems that include buttweld fittings, detailing flange specifications that ensure compatibility and integrity of the overall system.

AS/NZS 4087:2011 Metallic flanges for waterworks purposesSimilar to AS 2129, while it focuses on flanges, the specifications ensure the integration of buttweld fittings in systems requiring flanged connections, ensuring compatibility and performance integrity.

- High Strength:Carbon steel is known for its considerable strength, making it suitable for heavy-duty applications.

- Durability: This material exhibits excellent durability, capable of withstanding significant wear and tear over time.

- Cost-Effectiveness: Compared to other metal alloys, carbon steel is more affordable, offering a cost-effective solution for a wide range of applications.

- Malleability: Carbon steel is easily shaped and formed, allowing for the creation of a variety of components and fittings.

- Weldability: It can be welded with relative ease, facilitating simple fabrication and repair processes.

- Versatility: Carbon steel is used in numerous industries, including construction, automotive, shipping and manufacturing, due to its versatile properties.

- Recyclability: This material is highly recyclable, contributing to environmental sustainability and reducing the need for virgin resources.

- Conductivity: Carbon steel has good electrical conductivity, making it useful in applications requiring the transfer of electric current.

- Thermal Expansion: It has a predictable rate of thermal expansion, which is crucial for applications involving changes in temperature.

- Availability: Carbon steel is readily available in various grades and specifications, ensuring that there is a suitable type for nearly any application.