Stainless Pipe Fittings

Valve Warehouse Australia offers an extensive selection of high-grade 316 Stainless Steel Threaded Pipe Fittings, known for their versatility and engineered to meet Australian and International Standards. These fittings serve crucial functions across a wide range of Australian industries and sectors, including hospitality, dairy farms, food manufacturing, pharmaceuticals, and marine applications.

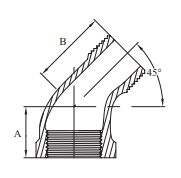

Our Stainless Pipe Fittings are engineered and manufactured to provide a versatile solution that is durable, food grade and corrosion resistance. Our 316 Stainless Steel Fittings demonstrate enormous resilience against temperatures of up to 180°C (356°F), with tensile strengths up to 5800kPa. Our stocked inventory of Stainless Steel Threaded Fittings includes 300mm length schedule 40 threaded pipes, hex nipples, sockets, hose connectors, elbows, reducing bush, hose barbs, adaptors, plugs, and caps. With a diverse size range spanning from 1/8” (6mm) to 4” (100mm), you are sure to find the perfect fit. To demonstrate our confidence in our products, we provide a 2-year warranty on all our Stainless Steel Threaded & Pipe Fittings.

Our Online Valve & Fitting Superstore has a large collection of competitively priced 316 Stainless Steel Fittings in Australia. With hundreds of Stainless plumbing products and sizes, our extensive inventory ensures that you’ll discover precisely what your project needs, all at competitive prices. With the added bonuses of Flat Rate Shipping Australia-Wide and Volume Discounts of up to 20% OFF, you could secure one of the best deals in Australia.

Fittings that meet Australian Standards & Conditions

Our Stainless Steel Threaded Pipe Fittings meet AS/NZS 4020 and ASTM A403 standards, ensuring not only compliance but surpassing the rigorous benchmarks set forth. Crafted to ASTM A312 specs, they ensure durability in demanding applications. 316 Stainless Steel offers superior abrasion resistance due to its high tensile strength and low friction. It maintains structural integrity over time, ensuring long-lasting performance in diverse, demanding industrial settings.

Secure Your Pipes & Fittings with Our Range of Norma Hose Clamps

When working with Stainless Steel Hose Barbs, it's essential to properly secure your hose to the hose barb, to ensure a leak-free flow, whilst operating at high pressures with resistance to corrosion. Explore our selection of Norma Stainless Steel Hose Clamps for strong connections.

Our Team is here to help!

Our experienced team, with over 100 years of collective expertise in plumbing and fittings, stands ready to assist you. Whether you need guidance or advice for your next project, our knowledgeable team is here to help. Contact us today at info@valvewarehouseaustralia.com.au or call (03) 9421 0042.

Frequently Asked Questions

Austenitic: Common, corrosion-resistant (304, 316, 321, 347) - Typical Operating Temperatures -200°C to 800°C (-330°F to 1470°F).

Ferritic: Good corrosion resistance, magnetic (430, 409, 439) Typical Operating Temperatures -100°C to 700°C (-150°F to 1300°F).

Martensitic: High strength, hardness, and magnetic (410, 420, 440) Typical Operating Temperatures -100°C to 600°C (-150°F to 1110°F).

Duplex: Strong and corrosion-resistant (2205, 2507) Typical Operating Temperatures -50°C to 300°C (-58°F to 570°F).

Precipitation Hardening: High strength through heat treatment (17-4PH, 15-5PH) Typical Operating Temperatures -100°C to 500°C (-150°F to 930°F).

High Temperature Austenitic: For elevated temperature applications (310, 253MA) Typical Operating Temperatures 600°C to 1150°C (1110°F to 2100°F).

Super Austenitic: Exceptional corrosion resistance (Alloy 20, AL-6XN) Typical Operating Temperatures -100°C to 400°C (-150°F to 750°F).

*Please note that these are general ranges, and actual operating conditions may vary based on specific applications, alloy compositions, and other factors. It's important to consult relevant standards, codes, and engineering guidelines for precise temperature and pressure limits in specific applications.

304 Stainless Steel

- • Composition: Contains around 18% chromium and 8% nickel.

- • Characteristics: Common, good corrosion resistance.

- • Applications: Everyday items like kitchen equipment.

316 Stainless Steel

- • Composition: Contains additional elements like molybdenum.

- • Characteristics: Enhanced corrosion resistance, especially in marine and acidic environments.

- • Applications: Marine applications, medical devices, chemical processing equipment, medical implants and devices, coastal and marine structures.

321 Stainless Steel

- • Composition: Contains titanium.

- • Characteristics: Resists corrosion at high temperatures.

- • Applications: Exhaust systems, aircraft components.

347 Stainless Steel:

- • Composition: Contains niobium.

- • Characteristics: Similar to 321 but with improved high-temperature resistance.

- • Applications: Jet engines, furnaces, chemical processing equipment.

When working with stainless steel, it's best to avoid pairing it with plain carbon steel to prevent galvanic corrosion. Instead, use materials that have similar electrochemical properties to stainless steel, such as other stainless steel grades (e.g., using 304 stainless steel with 316 stainless steel) or metals like nickel, titanium, or copper. These materials are less likely to cause galvanic corrosion when in contact with stainless steel. If you must use dissimilar metals, consider using insulation, coatings, or isolating materials to prevent direct contact and minimize the risk of galvanic corrosion.