Carbon Steel Buttweld Fittings Standard

Experience the robust reliability of Carbon Steel Buttweld Fittings. Designed to ASTM A234 standards, these fittings are essential for efficient fluid control in industrial piping systems across oil, gas, and power generation sectors, ensuring durability and seamless integration.

$1.71 – $3,578.19 Inc. GST

Carbon Steel Buttweld Fittings

Valve Warehouse Australia proudly offers high-quality Carbon Steel Buttweld Fittings, meticulously crafted from carbon alloy steel conforming to ASTM A234 standards. These fittings are indispensable components across untold industrial applications, from oil and gas transport to power generation.

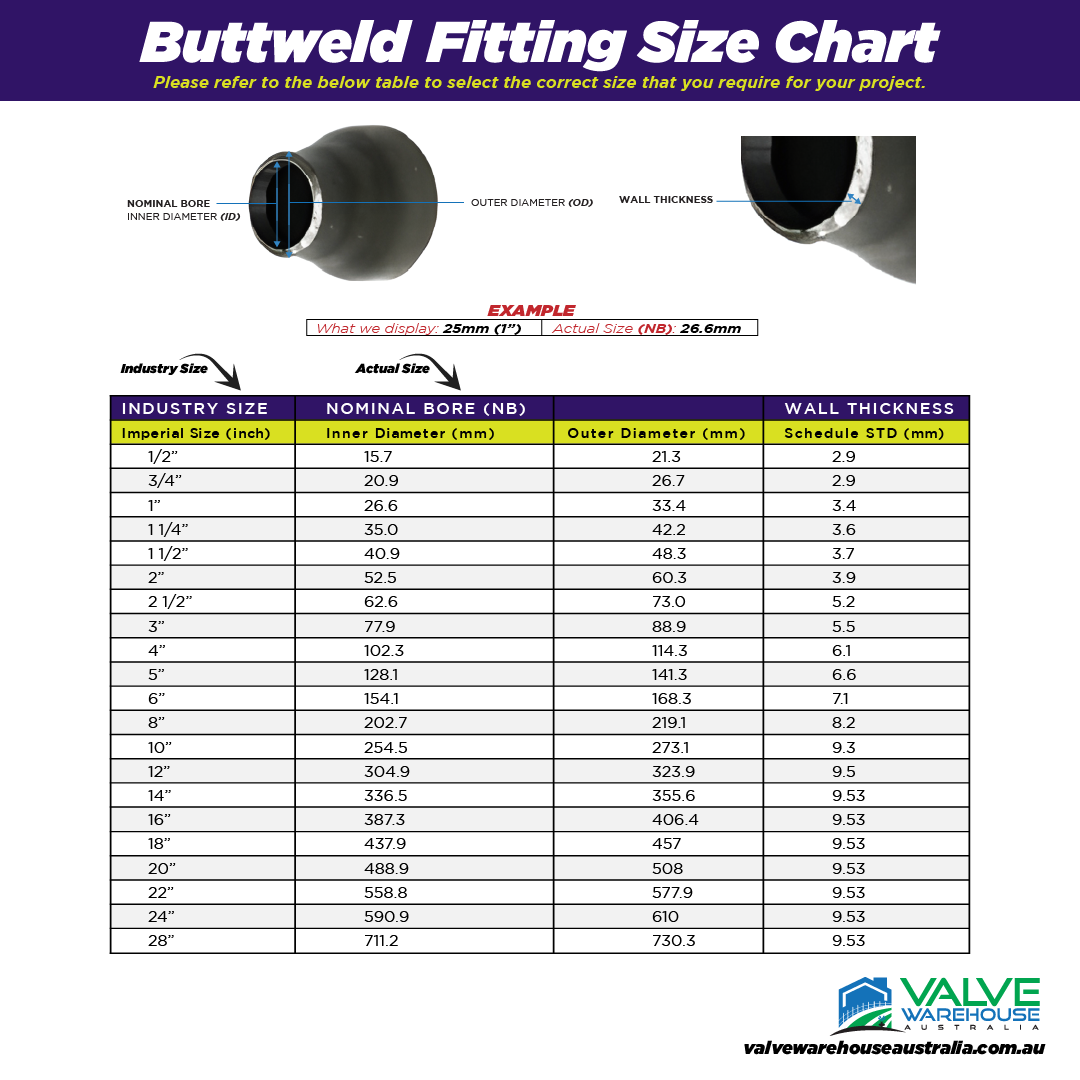

Sizing

Sizing is based off Nominal Bore (NB).

Nominal Bore (NB) is a term used in piping and tubing to specify the approximate internal diameter of the pipe. It is a standardized measurement that helps in ensuring compatibility and consistency in piping systems.

NB is commonly used in plumbing, heating, and industrial piping to ensure that pipes, fittings, and valves can be matched and connected efficiently.

Design and Applications

Carbon Steel Buttweld Fittings are engineered for robustness and reliability, suitable for complex piping systems utilised in various sectors such as petroleum, chemical, power plants, and shipbuilding. The versatility of these fittings allows them to perform essential functions like changing flow directions, branching off, or mechanically joining system components.

Build Quality and Advantages

The fittings are designed to ensure a permanent, leakproof connection when welded, offering a seamless and sturdy metal structure between the pipe and the fitting. This integration not only enhances the strength of the piping system but also ensures minimal space usage. The smoother inner surface and the gradual directional changes notably reduce pressure losses and turbulence, minimising corrosion and abrasion over time.

Operational Efficiency

Buttweld fittings are known for their operational efficiency and durability. The integrity of their construction allows them to handle demanding conditions, including high pressures and extreme temperatures, without compromising system integrity. Their implementation in a welded system is ideal for maintaining continuous and unobstructed flow, ensuring that systems operate at peak efficiency with reduced maintenance requirements.

Key Specifications

Manufactured from carbon alloy steel, these fittings meet rigorous industry standards and are suitable for numerous industrial applications. Their robust construction makes them ideal for environments where the flow of liquids and gases needs regulation. Commonly utilised in industries such as oil & gas, irrigation, plumbing, wastewater management, power generation, and much more, these fittings are designed to be a long-lasting solution in professional piping systems.

Whether for new construction or maintenance, the adaptability and resilience of our Carbon Steel Buttweld Fittings make them a must-have for any serious industrial application. They exceed the requirements for a secure, efficient, and reliable pipeline system, establishing themselves as a cornerstone in the industry.

Choose Valve Warehouse Australia’s Buttweld Fittings for assured quality and performance in your next project.

| Imperial Size | A | B | C | Wall Thickness | Apporx KG/PC |

|---|---|---|---|---|---|

| 1/2 | 21.3 | 15.7 | 38.1 | 2.8 | 0.08 |

| 3/4 | 26.7 | 20.9 | 38.1 | 2.9 | 0.08 |

| 1 | 33.4 | 26.6 | 38.1 | 3.4 | 0.15 |

| 1-1/4 | 42.2 | 35.0 | 47.8 | 3.6 | 0.16 |

| 1-1/2 | 48.3 | 40.9 | 57.2 | 3.7 | 0.4 |

| 2 | 60.3 | 52.5 | 76.2 | 3.9 | 0.7 |

| 2-1/2 | 73.0 | 62.6 | 95.2 | 5.2 | 1.3 |

| 3 | 88.9 | 77.9 | 114.3 | 5.5 | 2.0 |

| 3-1/2 | 101.6 | 90.2 | 133.4 | 5.7 | 2.8 |

| 4 | 114.3 | 102.3 | 152.4 | 6.1 | 3.8 |

| 5 | 141.3 | 128.1 | 190.5 | 6.6 | 6.5 |

| 6 | 168.3 | 154.1 | 228.6 | 7.1 | 10.1 |

| 8 | 219.1 | 202.7 | 304.8 | 8.2 | 20.1 |

| 10 | 273.1 | 254.5 | 381.0 | 9.3 | 36.0 |

| 12 | 323.9 | 304.9 | 457.2 | 9.5 | 53.0 |

| 14 | 355.6 | 336.54 | 533 | 9.53 | 68.0 |

| 16 | 406.4 | 387.34 | 610 | 9.53 | 89.0 |

| 18 | 457 | 437.94 | 686 | 9.53 | 113.0 |

| 20 | 508 | 488.94 | 762 | 9.53 | 140.0 |

| 24 | 610 | 590.94 | 914 | 9.53 | 202.0 |

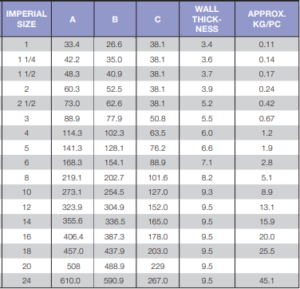

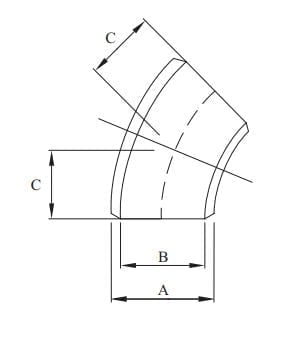

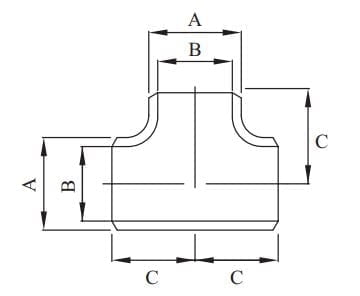

| Imperial Size | A | B | C | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|

| 1/2 | 21.3 | 15.7 | 15.7 | 2.8 | 0.04 |

| 3/4 | 26.7 | 20.9 | 19 | 2.9 | 0.04 |

| 1 | 33.4 | 26.6 | 22.4 | 3.4 | 0.08 |

| 1-1/4 | 42.2 | 35 | 25.4 | 3.6 | 0.08 |

| 1-1/2 | 48.3 | 40.9 | 28.4 | 3.7 | 0.2 |

| 2 | 60.3 | 52.5 | 35.1 | 3.9 | 0.35 |

| 2-1/2 | 73 | 62.6 | 44.4 | 5.2 | 0.7 |

| 3 | 88.9 | 77.9 | 50.8 | 5.5 | 1.1 |

| 4 | 114.3 | 102.3 | 63.5 | 6.1 | 1.9 |

| 5 | 141.3 | 128.1 | 79.2 | 6.6 | 3.3 |

| 6 | 168.3 | 154.1 | 95.2 | 7.1 | 5.0 |

| 8 | 219.1 | 202.7 | 127 | 8.2 | 10.0 |

| 10 | 273.1 | 254.5 | 158.8 | 9.3 | 18.0 |

| 12 | 323.9 | 304.9 | 190.5 | 9.5 | 26.5 |

| 14 | 355.6 | 336.54 | 222.0 | 9.5 | 34.0 |

| 16 | 406.4 | 387.34 | 254.0 | 9.5 | 44.5 |

| 18 | 457.0 | 437.94 | 286.0 | 9.5 | 56.5 |

| 20 | 508 | 488.94 | 318.0 | 9.5 | |

| 24 | 610 | 590.94 | 381.0 | 9.5 | 101.0 |

| Imperial Size | A | B | C | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|

| 1 | 33.4 | 26.6 | 25.4 | 3.4 | 0.10 |

| 1-1/4 | 42.2 | 35.0 | 31.8 | 3.6 | 0.17 |

| 1-1/2 | 48.3 | 40.9 | 38.1 | 3.7 | 0.24 |

| 2 | 60.3 | 52.5 | 50.8 | 3.9 | 0.44 |

| 2-1/2 | 73.0 | 62.6 | 63.5 | 5.2 | 0.8 |

| 3 | 88.9 | 77.9 | 76.2 | 5.5 | 1.34 |

| 3-1/2 | 101.6 | 90.2 | 89 | 5.7 | 1.9 |

| 4 | 114.3 | 102.3 | 101.6 | 6.1 | 2.6 |

| 5 | 121.3 | 128.1 | 127.0 | 6.6 | 4.3 |

| 6 | 168.3 | 154.1 | 152.4 | 7.1 | 6.6 |

| 8 | 219.1 | 202.7 | 203.2 | 8.2 | 13.5 |

| 10 | 273.1 | 254.5 | 254.0 | 9.3 | 23.6 |

| 12 | 323.9 | 304.9 | 304.8 | 9.5 | 34.6 |

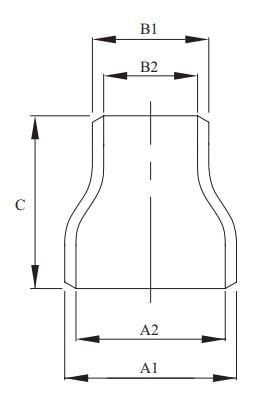

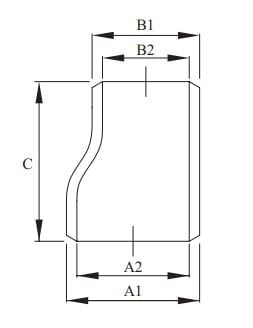

| Imperial Size | Larger Diameter A1 | Larger Diameter A2 | Smaller Diameter B1 | Smaller Diameter B2 | End to End C | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|---|---|

| 3/4 x 1/2 | 26.7 | 20.9 | 21.3 | 15.7 | 38.1 | 2.9 | 0.06 |

| 1 x 1/2 | 33.4 | 26.6 | 21.3 | 20.9 | 50.8 | 3.4 | 0.1 |

| 1 x 3/4 | 33.4 | 26.6 | 26.7 | 20.9 | 50.8 | 3.4 | 0.1 |

| 1 1/4 x 3/4 | 42.2 | 35 | 26.7 | 20.9 | 50.8 | 3.6 | 0.2 |

| 1 1/4 x 1 | 42.2 | 35 | 33.4 | 26.6 | 50.8 | 3.6 | 0.2 |

| 1 1/2 x 1 | 48.3 | 40.9 | 21.3 | 15.7 | 63.5 | 3.7 | 0.2 |

| 1 1/2 x 1 1/4 | 48.3 | 40.9 | 26.7 | 20.9 | 63.5 | 3.7 | 0.2 |

| 1 1/2 x 1 1/2 | 48.3 | 40.9 | 33.4 | 26.6 | 63.5 | 3.7 | 0.3 |

| 2 x 3/4 | 60.3 | 52.5 | 26.7 | 20.9 | 76.2 | 3.9 | 0.4 |

| 2 x 1 | 60.3 | 52.5 | 33.4 | 26.6 | 76.2 | 3.9 | 0.4 |

| 2 x 1 1/4 | 60.3 | 52.5 | 42.2 | 35 | 76.2 | 3.9 | 0.5 |

| 2 x 1 1/2 | 60.3 | 52.5 | 48.3 | 40.9 | 76.2 | 3.9 | 0.6 |

| 2 1/2 x 1 1/4 | 73 | 62.6 | 42.2 | 35 | 88.9 | 5.2 | 0.8 |

| 2 1/2 x 1 1/2 | 73 | 62.6 | 48.3 | 40.9 | 88.9 | 5.2 | 0.9 |

| 3 x 1 | 88.9 | 77.9 | 33.4 | 26.6 | 88.9 | 5.5 | 0.9 |

| 3 x 1 1/2 | 88.9 | 77.9 | 48.3 | 40.9 | 88.9 | 5.5 | 1 |

| 3 x 2 | 88.9 | 77.9 | 60.3 | 52.5 | 88.9 | 5.5 | 1.1 |

| 3 x 2 1/2 | 88.9 | 77.9 | 73 | 62.6 | 88.9 | 5.5 | 1.3 |

| 4 x 2 | 114.3 | 102.3 | 60.3 | 52.5 | 101.6 | 6.4 | 1.5 |

| 4 x 2 1/2 | 114.3 | 102.3 | 73 | 62.6 | 101.6 | 6.4 | 1.6 |

| 4 x 3 | 114.3 | 102.3 | 88.9 | 77.9 | 101.6 | 6.4 | 2 |

| 5 x 3 | 141.3 | 128.1 | 88.9 | 77.9 | 127 | 6.6 | 2.5 |

| 5 x 4 | 141.3 | 128.1 | 114.3 | 102.3 | 127 | 6.6 | 2.6 |

| 6 x 2 1/2 | 168.3 | 154.1 | 73 | 62.6 | 139.7 | 7.1 | 3.7 |

| 6 x 3 | 168.3 | 154.1 | 88.9 | 77.9 | 139.7 | 7.1 | 3.6 |

| 6 x 4 | 168.3 | 154.1 | 114.3 | 102.3 | 139.7 | 7.1 | 3.5 |

| 6 x 5 | 168.3 | 154.1 | 141.3 | 128.1 | 139.7 | 7.1 | 3.7 |

| 8 x 4 | 219.1 | 202.7 | 114.3 | 102.3 | 152.4 | 8.2 | 6.3 |

| 8 x 5 | 219.1 | 202.7 | 141.3 | 128.1 | 152.4 | 8.2 | 5.9 |

| 8 x 6 | 219.1 | 202.7 | 168.3 | 154.1 | 152.4 | 8.2 | 5 |

| 10 x 6 | 273.1 | 254.6 | 168.3 | 154.1 | 177.8 | 9.5 | 10 |

| 10 x 8 | 273.1 | 254.6 | 219.1 | 202.7 | 177.8 | 9.5 | 10.3 |

| 12 x 6 | 323.9 | 304.9 | 168.3 | 154.1 | 203.2 | 9.5 | 15.2 |

| 12 x 8 | 323.9 | 304.9 | 219.1 | 202.7 | 203.2 | 9.5 | 15.3 |

| 12 x 10 | 323.9 | 304.9 | 273.1 | 254.5 | 203.2 | 9.5 | 15.3 |

| 14 x 10 | 355.6 | 336.5 | 273.1 | 254.5 | 203.2 | 9.5 | 20 |

| 14 x 12 | 355.6 | 336.5 | 323.9 | 304.9 | 203.2 | 9.5 | 20 |

| 16 x 10 | 406.4 | 387.3 | 273.1 | 254.5 | 356 | 9.5 | 25 |

| 16 x 12 | 406.4 | 387.3 | 323.9 | 304.9 | 356 | 9.5 | 25 |

| 16 x 14 | 406.4 | 387.3 | 355.6 | 336.5 | 356 | 9.5 | 25 |

| 18 x 14 | 457 | 437.9 | 355.6 | 336.5 | 381 | 9.5 | 40 |

| 18 x 16 | 457 | 437.9 | 406.4 | 387.3 | 381 | 9.5 | 40 |

| 20 x 16 | 508 | 488.9 | 406.4 | 387.3 | 508 | 9.5 | 61 |

| 24 x 20 | 610 | 590.9 | 508 | 488.9 | 508 | 9.5 | 77 |

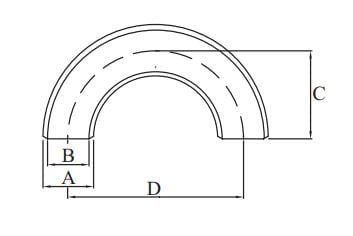

| Imperial Size | A | B | C | D | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|---|

| 3/4 | 26.7 | 20.9 | 28.4 | 76.2 | 2.9 | 0.16 |

| 1 | 33.4 | 26.6 | 38.1 | 76.2 | 3.4 | 0.3 |

| 1-1/4 | 42.2 | 35.0 | 47.8 | 95.6 | 3.6 | 0.32 |

| 1-1/2 | 48.3 | 40.9 | 57.2 | 114.4 | 3.7 | 0.8 |

| 2 | 60.3 | 52.5 | 76.2 | 152.4 | 3.9 | 1.4 |

| 2-1/2 | 73.0 | 62.6 | 95.2 | 190.4 | 5.2 | 2.6 |

| 3 | 88.9 | 77.9 | 114.3 | 228.6 | 5.5 | 4.0 |

| 4 | 114.3 | 102.3 | 152.4 | 304.8 | 6.1 | 7.6 |

| Imperial Size | A | B | C | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|

| 1/2 | 22 | 15.7 | 25 | 2.9 | 0.1 |

| 3/4 | 26.7 | 20.9 | 28.4 | 2.9 | 0.16 |

| 1 | 33.4 | 26.6 | 38.1 | 3.4 | 0.36 |

| 1-1/4 | 42.2 | 35.0 | 47.8 | 3.6 | 0.5 |

| 1-1/2 | 48.3 | 40.9 | 57.2 | 3.7 | 0.7 |

| 2 | 60.3 | 52.5 | 63.5 | 3.9 | 1.0 |

| 2-1/2 | 73.0 | 62.6 | 76.2 | 5.2 | 1.8 |

| 3 | 88.9 | 77.9 | 85.9 | 5.5 | 2.7 |

| 4 | 114.3 | 102.3 | 104.6 | 6.1 | 4.4 |

| 5 | 141.3 | 128.1 | 124.0 | 6.6 | 7.0 |

| 6 | 168.3 | 154.1 | 142.7 | 7.1 | 10.0 |

| 8 | 219.1 | 202.7 | 177.8 | 8.2 | 19.0 |

| 10 | 273.1 | 254.5 | 215.9 | 9.3 | 30.0 |

| 12 | 323.9 | 304.9 | 254.0 | 9.5 | 47.0 |

| 14 | 355.6 | 336.5 | 279.0 | 9.5 | 60.0 |

| 16 | 406.4 | 387.3 | 305.0 | 9.5 | 75.0 |

| 18 | 457.0 | 437.9 | 343.0 | 9.5 | 96.0 |

| 20 | 508.0 | 488.9 | 381 | 9.5 | 115.0 |

| 24 | 610.0 | 590.9 | 432.0 | 9.5 | 139.0 |

| Imperial Size | Larger Diameter A1 | Larger Diameter A2 | Smaller Diameter B1 | Smaller Diameter B2 | End to End C | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|---|---|

| 1 x 1/2 | 33.7 | 25.9 | 21.3 | 15.7 | 50.8 | 3.4 | 0.1 |

| 1 x 3/4 | 33.7 | 25.9 | 26.7 | 20.9 | 50.8 | 3.4 | 0.1 |

| 1-1/4 x 1 | 42.2 | 35 | 33.7 | 25.9 | 50.8 | 3.6 | 0.2 |

| 1-1/2 x 1/2 | 48.3 | 40.9 | 21.3 | 15.7 | 63.5 | 3.7 | 0.3 |

| 1-1/2 x 1-1/4 | 48.3 | 40.9 | 33.7 | 25.9 | 76.2 | 3.7 | 0.3 |

| 2 x 1 | 60.3 | 52.5 | 48.3 | 40.9 | 76.2 | 3.9 | 0.4 |

| 2 x 1 1/2 | 60.3 | 62.6 | 48.3 | 40.9 | 88.9 | 3.9 | 0.7 |

| 2-1/2 x 1-1/2 | 73 | 62.6 | 48.3 | 40.9 | 88.9 | 5.2 | 0.6 |

| 2-1/2 x 2 | 73 | 62.6 | 48.3 | 40.9 | 88.9 | 5.2 | 0.6 |

| 3 x 2 | 88.9 | 77.9 | 60.3 | 52.5 | 88.9 | 5.5 | 0.9 |

| 3 x 2-1/2 | 88.9 | 77.9 | 73.0 | 62.6 | 101.6 | 5.5 | 1.0 |

| 4 x 2 | 114.3 | 102.3 | 60.3 | 52.5 | 101.6 | 6.1 | 1.5 |

| 4 x 2-1/2 | 114.3 | 102.3 | 73.0 | 62.6 | 101.6 | 6.1 | 1.6 |

| 4 x 3 | 114.3 | 102.3 | 88.9 | 76.7 | 101.6 | 6.1 | 1.6 |

| 5 x 4 | 141.3 | 128.1 | 114.3 | 102.3 | 127 | 6.6 | 2.6 |

| 6 x 3 | 168.3 | 154.1 | 88.9 | 77.9 | 139.7 | 7.1 | 3.5 |

| 6 x 4 | 168.3 | 154.1 | 114.3 | 102.3 | 139.7 | 7.1 | 3.6 |

| 6 x 5 | 168.3 | 154.1 | 141.3 | 128.1 | 139.7 | 7.1 | 3.7 |

| 8 x 4 | 219.1 | 202.7 | 114.3 | 154.1 | 152.4 | 8.2 | 6.3 |

| 8 x 5 | 219.1 | 202.7 | 141.3 | 154.1 | 152.4 | 8.2 | 5.9 |

| 8 x 6 | 219.1 | 202.7 | 168.3 | 154.1 | 152.4 | 8.2 | 5.9 |

| 10 x 6 | 273.1 | 254.5 | 168.3 | 154.1 | 177.8 | 9.3 | 10.0 |

| 10 x 8 | 273.1 | 254.5 | 219.1 | 202.7 | 177.8 | 9.3 | 10.7 |

| 12 x 8 | 323.9 | 304.9 | 219.1 | 202.7 | 203.2 | 9.5 | 15.3 |

| 12 x 10 | 323.9 | 304.9 | 273.1 | 254.4 | 203.2 | 9.5 | 15.7 |

| Imperial Size | Larger Diameter A1 | Larger Diameter A2 | Smaller Diameter B1 | Smaller Diameter B2 | Centre to End C1 | Centre to End C2 | Wall Thickness | Approx KG/PC |

|---|---|---|---|---|---|---|---|---|

| 2 x 1 | 60.3 | 52.5 | 33.4 | 26.6 | 63.5 | 63.5 | 3.9 | 1.1 |

| 2 x 1-1/2 | 60.3 | 52.5 | 48.3 | 40.9 | 63.5 | 63.5 | 3.9 | 1.0 |

| 2-1/2 x 2 | 73.0 | 62.6 | 60.3 | 52.5 | 76.2 | 69.8 | 5.2 | 1.9 |

| 3 x 2 | 88.9 | 77.9 | 60.3 | 52.5 | 85.9 | 82.6 | 5.5 | 2.4 |

| 3 x 2 1/2 | 88.9 | 77.9 | 73.0 | 62.6 | 85.9 | 82.6 | 5.5 | 2.4 |

| 4 x 3 | 114.3 | 102.3 | 88.9 | 77.9 | 104.6 | 98.6 | 6.1 | 4.0 |

| 6 x 4 | 168.3 | 154.1 | 114.3 | 102.3 | 142.7 | 130.0 | 7.1 | 9.5 |

| 8 x 6 | 219.1 | 202.7 | 168.3 | 154.1 | 177.8 | 168.1 | 8.2 | 18.0 |

All products are covered by the full manufacturer’s warranty of 2 years. Should you have an item that is faulty we are happy to replace with a new one. Please contact us with details and/or photos of the fault as well as your contact details so we can discuss the issue and organise a replacement at our cost, or if you prefer we can provide a full refund. In some cases, we may request the item be returned to us depending on the issue.

| Material | Carbon Steel Buttweld |

|---|

63mm Liquid Filled Dial Bottom Entry Vacuum Gauge

63mm Liquid Filled Dial Bottom Entry Vacuum Gauge